Bespoke manufacturing solutions for your unique needs

Nelson Miller Group manages the end-to-end manufacturing process of your custom components and devices across a wide range of industries.Extending your reach to build better, more advanced products

While we built our reputation on nameplates, switches, controls, and electronic components and devices, our customers now depend on us to deliver complex, complete devices that integrate advanced technologies, optimize costs, and enable PPV. What separates us from other strategic outsourcing partners is our ability to tackle some of your most unique needs and find solutions that are either outside your reach or area of expertise.

We serve customers in so many industries that it’s impossible to list them all—but just to name a few: medical, lighting, aerospace, IoT, consumer electronics, industrial, telecommunication, security, beauty, and construction.

Manufacturing solutions—medical and industrial HMIs

At the onset Human Machine Interfaces (HMIs) are controls – NMG has superior expertise in the design and manufacturing of switches, buttons, keyboards, touch screens, joystick controllers, remotes, wearables, panels, handles, and pendants (thumb, finger, hand) – whether manually or digitally activated.

Our engineering know-how encompasses sensors, ruggedness, enclosure/casings, internal circuitry, durability, connections, attachments and installation, output signal, multi-axis, component placement and layout, labeling, wiring and cabling, power distribution, light indicators, weight, and ergonomics.

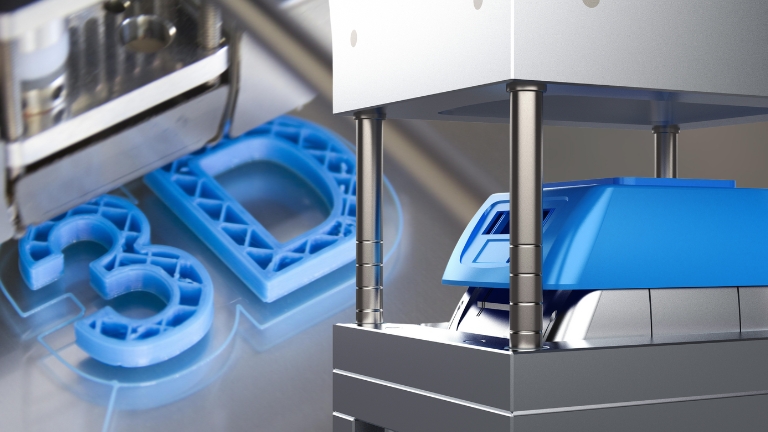

We particularly understand the needs of the industrial and medical sectors and their focus on the end-user experience. We create point-of-care, portable diagnostic, monitoring, and wearable medical devices. On the industrial front, we design and produce HMI interfaces for demanding environmental conditions. NMG brings expertise in key technologies such as advanced materials, precision molding manufacturing, connectivity, and miniaturization. Companies like Haas, Bayer, Medtronics and Kohler trust NMG.

Components for electronic devices

In our experience, many OEMS have their own product designs; therefore, most standard electronic components won’t work. We have superior expertise in manufacturing custom passive, interconnected, electro-mechanical, rubber, plastic, metallic, and printed or pcb electronics components. We engage with partners that have world-class R&D and engineering teams, highly automated processes, high-level raw materials, and well- LEDs established quality control to properly manufacture a wide range of passive electronic components.

We focus on design, digital simulation, thorough testing, and material characterization to bring superior value. We believe we can help you avoid up to 90% of potential issues prior to production, shorten your lead time, deliver superior quality products, prevent costly adjustments and retooling, and solidify your business reputation. We’re the proud component partner for many of Acuity Brands’ and Lutron’s products.

Electronic devices

We’ve been designing and producing switches since our inception. We’re intimately familiar with the large variety of manufacturing processes, architecture, and materials involved when producing electronic devices. Our designs match your unique applications and stringent cosmetic requirements, resulting in highly functional and reliable switches.

Manufacturing electronic devices involves several key steps to ensure their successful production. The process begins with designing the electronic device; then sourcing electronic components, modules, and other hardware elements; completing printed circuit board (PCB) assembly and testing; and ending with final assembly.

NMG brings extraordinary value when any one of these steps require a very unique approach, usually associated with a specific industry. For example, IoT/networking devices require connectivity and data-sharing capabilities; police and security devices demand extreme ruggedness; beauty tech products ask for stronger aesthetics and ergonomics, accurate measurements, controlled temperatures, or specific timing.

The world has become increasingly reliant on electronics, requiring devices to perform more precisely and consistently. Throughout the entire manufacturing process, attention to quality control, adherence to industry standards, and compliance with regulatory requirements are essential to ensure the reliability, performance, and safety of your electronic devices.

NMG has delivered products as diverse as gateway routers, nail polish dryers, wireless wine cooler controls, hospital bed lighting systems, and 6-foot-tall outdoor kiosks. We love solving the challenges of manufacturing any electronic device.

Nameplates

We offer the most extensive metal and plastic nameplate processing capabilities in the industry. This means that we can leverage the widest range of technologies to design the exact nameplate you need. With NMG, your design possibilities are endless: We understand multi-color metal anodizing, serializing and UID barcoding, etching and filling, laser etching, silkscreen and digital printing, and polyurethane-domed nameplates.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.