Quality assurance and manufacturing services

Nelson Miller Group carefully oversees manufacturing and testing to ensure a great product.You need the right product, at the right price, at the right time.

Our Total Quality Management approach uses robust processes and flexible systems to deliver your product right the first time, every time. We maintain rigorous quality assurance while ensuring your cost and time constraints are met.

We stand behind the product we deliver to you, and we aren’t happy until you're happy.

Decades of experience backed by uncompromising quality control

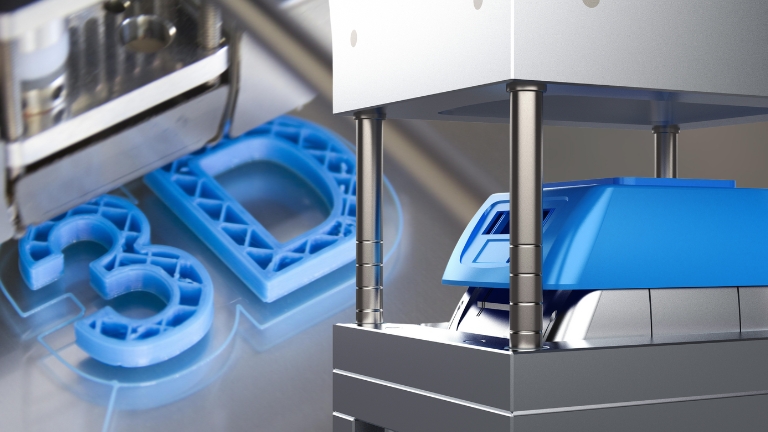

Since our inception in 1937, we’ve come to understand the complexities of the product manufacturing process and the critical importance of producing a quality product. Through the decades, we’ve gained proficiency in numerous manufacturing operations related to plastics, metals, and electronics, including CNC machining, extrusion, injection molding, casting, printed electronics, and more. This expertise in product manufacturing allows us to recommend the right methods for your product’s individualized requirements related to production volume, application, cost, and quality.

We understand that experience alone doesn’t always guarantee a quality product. Our commitment to testing, inspection, and quality assurance processes helps us identify and resolve issues quickly. This commitment has earned NMG multiple third-party certifications and accreditations, including ISO (9001:2015 and AS 9100D) and ITAR certifications, as well as NADCAP approval for anodizing.

Our approach to quality assurance

Selection criteria

- Capabilities review

- On-site visit

- Production capacity

- Process controls

- Certification

Product specifications

- RFQ

- Drawings (2D/3D) and golden samples

- Design for Manufacturability (DFM)

Inspections and approvals

- Raw material certifications

- First Article Inspection (FAI)

- Function and performance testing

- Final packaging validation

- Certificate of conformance

- Part Production Approval Process (PPAP)

Change management

- Engineering Change Notification (ECN)

- Engineering Change Request (ECR)

- Document control

Performance management

- Pre-Shipment Inspection (PSI) report

- Corrective action reports (8D/A3)

- Quarterly business review

- KPI measurement

- Continuous improvement

- Risk management

Learn more about our capabilities and the steps we take to ensure a consistent quality product and process:

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.