Lower production costs, boost your bottom line.

Our team is an extension of your team, and we’re committed to helping you lower your costs without sacrificing quality.Ensure your business not just survives, but thrives.

As a manufacturer, you face intense pressure to keep your pricing competitive and increase your gross margins. Lowering your costs must align with high customer expectations for product quality, performance, and service. Finding a partner to help you achieve these goals can be challenging. Your products are unique. You are not looking for a one-size-fits-all solution. You need something custom-tailored, that works for your specific needs. NMG provides you with strategic cost management solutions that help you reduce manufacturing and supply chain costs, and keep a clean balance sheet. We create financial stability for you while maintaining quality, service, and performance to meet customer expectations.

Our experts work with you to provide the most effective, efficient cost reduction strategies for manufacturers. When you outsource manufacturing with NMG, you will:

- Generate real savings and operational improvements.

- Access supply chain expertise and global markets without incurring new administrative and overhead costs.

- Make your product more competitive not just in the short term, but in the long term by creating positive PPV.

- Positively impact your financial performance and valuation.

- Benefit from our sourcing expertise during new product development, reducing development costs and improving the manufacturability of your parts while shrinking the concept-to-market timeframe.

- Simplify your procurement process for existing parts by allowing NMG to negotiate cost savings and purchase agreement terms with our proven network of suppliers, as well as reduce your margin stacking.

We always analyze your Total Cost of Ownership (TCO) and we don’t believe that any valid solution should only look at just the cost of manufacturing. We invite you to check out our TCO section using this link. The cost of manufacturing your product still accounts for a significant share of your overall cost. So how can manufacturing costs be reduced?

Here’s what we can do for you to lower costs in a meaningful, impactful way:

Leverage our relationships and access global sourcing.

NMG offers multiple domestic manufacturing sites and extensive strategic partnerships through our own global sourcing offices in the US and Asia.

We're not constrained by a single source, a line card, or a factory; you can access the right manufacturing site with the technology and competencies you need for your production volume. You don’t want to pay more for a factory that needs to run double shifts to reach the production volume you need. You don’t want MOQs that don’t give you any flexibility managing and adjusting your demand forecast. And you don’t want to be limited by technology and equipment that increase your lead time.

A global presence can generate labor cost savings. While the gap in labor costs between countries has shrunk, there remain regions with lower labor costs, providing access to a skilled workforce at a more competitive rate. This cost advantage can significantly lower costs of your overall manufacturing. This is especially true if your product requires more “human” assembly or touch than a highly automated or robotized assembly.

On your own, you might not be in a position to negotiate volume discounts for your custom parts. However, NMG uses our good standing and our other customers’ demand to get manufacturers’ attention, create economies of scale, and access favorable payment terms.

Additionally, NMG helps you identify alternative sources to reduce manufacturing costs, avoid reliance on one single supplier, circumvent margin stacking coming from multiple levels of wholesalers and distributors, and consolidate your AVL.

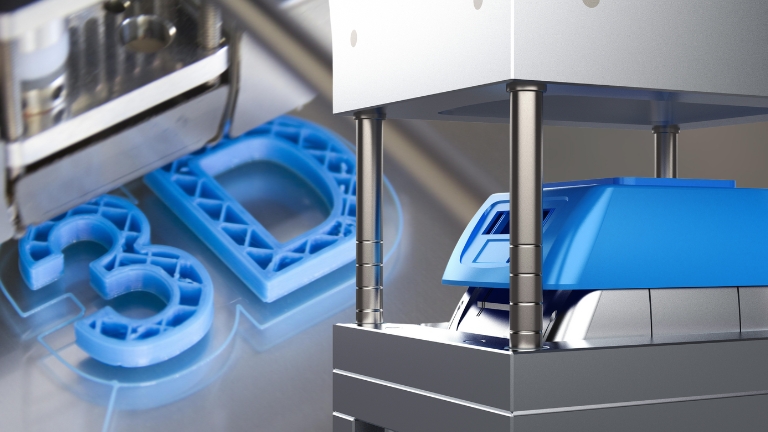

Maximize your product value with DFM.

At NMG, we understand that Design for Manufacturing (DFM) plays a central role in optimizing efficiency and reducing costs for manufacturers. Our commitment to innovative and strategic DFM practices allows manufacturers to confidently navigate the complexities of production while realizing substantial cost reductions. Our custom solutions streamline the entire product development lifecycle, ensuring that design considerations seamlessly integrate with manufacturing processes.

We provide design and re-design expertise through two distinct approaches. Value engineering (VE) is focused on lowering costs and improving quality in the initial product design phase. Value analysis (VA) is an approach that offers redesign expertise focused on identifying cost savings for your existing products. No matter where you are in the design process, NMG can help you optimize your product value by maintaining or enhancing functionality, without increasing costs.

Unlike other problem-solving approaches, value analysis and value engineering stand out for their emphasis on function analysis through a structured process:

1) Product assessment

2) Analysis of functionality and customer priorities

3) Identification of new methods to meet or surpass product requirements

Value engineering (VE)

We build VE into our engineering design process, proactively identifying potential challenges and addressing them during the design phase so that our customers do not have to engineer excessive costs out after their product is already in the market. Throughout our thorough process for new product introductions (NPIs), our mechanical, electronic, and firmware engineers advise you on the best materials, parts, and production methods to bring your product to life, while still controlling your costs.

Read our case study to learn more about how NMG provided DFM and value engineering support to an electric cart manufacturer to improve functionality and reduce costs on a newly introduced product.

Value Analysis (VA)

As a manufacturer, you need to understand where the unnecessary costs in your existing products lie and eliminate them. NMG has the tools to help you find these hidden costs, and the expertise to make innovative recommendations and enhancements to address them. Through our value analysis process, NMG empowers manufacturers to minimize material waste, enhance production speed, and improve overall product quality. Our expertise in VA not only results in cost savings through improved manufacturing processes but also facilitates the creation of products that are inherently more cost-effective to produce

NMG’s VE and VA approach help you improve your product’s manufacturability and reduce costs through a number of strategies:

- Evaluating material options. From resins and silicone rubber to metals and LEDs, NMG and our partners have expertise in material strength, durability, and tolerances to help you choose the most cost-effective, readily available, and suitable materials for your fabrication process.

- Designing for ease of assembly. We analyze your product’s assembly process while designing it to reduce production time, control costs, and limit potential issues that could arise.

- Lean manufacturing. We use lean manufacturing to strategically cut the costs associated with raw material processing. Through analysis of our supply chain and production processes, we identify areas of inefficiency and waste and optimize raw material utilization.

- Reducing waste. We prioritize scrap reduction by using strategies like multi-cavity injection molding. In our injection molding facility, we use multi-cavity molds that offer higher production output and lower costs per part, due to our decreased labor needs and operating time.

- Considering quality control. We implement quality control measures to ensure your product meets the required standards, reducing costs by limiting the number of defects, reworks, and returns. Paying special attention to quality control allows NMG to eliminate the costs associated with scrapping projects, while also building customer satisfaction and brand loyalty for your company.

Access transformative technology without making your own investment.

You likely don’t have infinite resources to invest in all the production processes and tools necessary to amplify efficiency, lower costs, minimize human errors, accelerate production rates, improve consistency and precision. Collaborating with NMG and our partners’ facilities provides access to transformative solutions. Leveraging your suppliers’ innovations, newer or more advanced equipment, automation, robotics, and even R&D can yield cost savings through enhanced manufacturing methods, more efficient materials utilization, and reduced cycle times and labor expenses.

When you outsource the manufacturing of a part, subassembly, or complete assembly, your manufacturing costs are lowered because you benefit from your partners’ investment in manufacturing equipment and process. For example, McKinsey reported a recent study indicating that typical machinery and equipment manufacturers are achieving cost reductions ranging from 5% to 20% through investments in cloud-enhanced digital transformation. These investments encompass various initiatives such as deploying industrial internet of things (IoT) sensors in manufacturing equipment to enhance visibility and reduce maintenance costs, implementing robotic automation on the factory floor, utilizing digital twins for process and design enhancements, and investing in machine learning and artificial intelligence for advanced manufacturing data analysis.

Optimize, synchronize, and consolidate your supply chain.

We help you create and maintain a custom supply chain by accessing reliable, global sourcing, minimizing the number of stages, and synchronizing your supply network. More on this in our Total Cost of Ownership (TCO) section.

Why NMG?

We have engineering talent, the global manufacturing footprint, strong partnerships, and the access to the transformative technology so you extract even more value than you thought was possible. When you need to lower costs, decide to outsource your manufacturing with NMG.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.